TRANSFORMER CORES

TRANSFORMER CORE MANUFACTURER in TURKEY

What is transformer core?

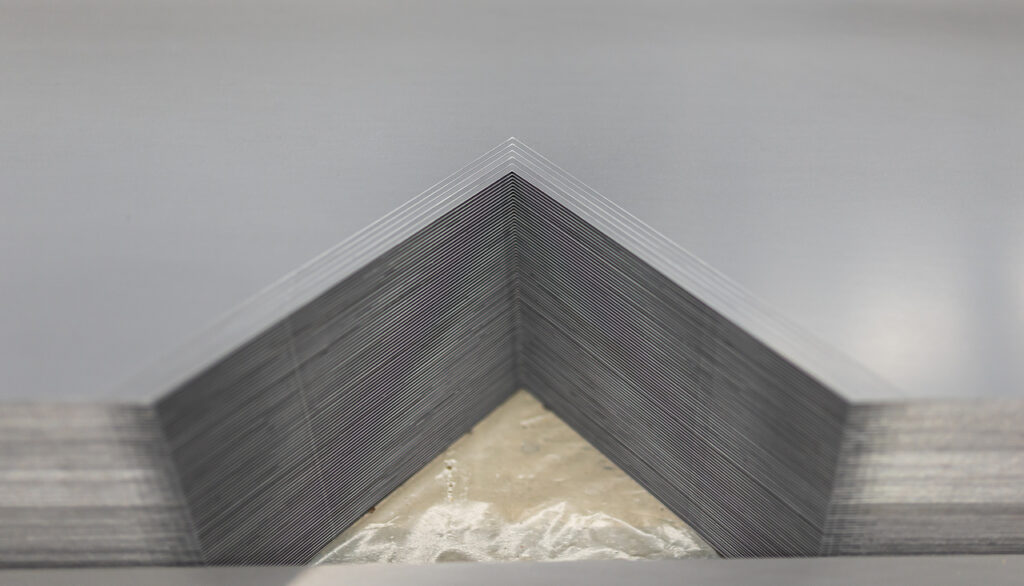

“Transformer core” can also be named as “heart of the transformer” . Cores transmit electricity within transformer. Transformer cores are made of electrical steel which is also known as “silicon steel”.

There are many kinds of silicon steel classified according to thickness and loss rates. Mainly they are classified as “CRGO” (Colled Rolled Grain Oriented), and “CRNGO” (Colled Rolled None Grain Oriented).

What is the difference between CRGO and CRNGO?

The main difference between them is the area of use. CRGO material reduces the core loss (electricity current).CRGO grades of electrical steel are used for transformer cores and generators. CRNGO fully processed steels are iron-silicon alloys and have similar magnetic properties in all directions.

What are the types of transformer cores?

There are three types of transformer cores; steel laminated, toroidal and solid. Types show variety according to the raw material that is used (thicknesses-losses) and area of use. Processing the material is also another important aspect of transformer core production.

What are cores in transformers made of?

Transformer cores are produced of electrical steel. There are many kinds of electrical steel according to thicknesses and elecricity losses. The classification varies from 023mm to 120mm with different loss rates such 075-085-095 / 1. Tesla.

Are transformer cores magnetic?

Yes, definitely the cores have high magnetic permeability.

Why cores are used in transformers?

The reason that cores are used in transformers is being produced of electrical steel which is a very good conductor of electricty. EasyCore uses the best quality of electrical steel to meet the demands of every customer.

How should we decide which cores to buy?

It’s very easy for you to get the fastest and detailed reply from EasyCore after you share the drawings of your projects with us. Our experts in transformer core production unit will decide to most appropriare sheets that will be used and inform you about the production and delivery timings.

What’s the monthly production capacity of EasyCore?

EasyCore has the capacity of producing 650 tons of transformer cores in a month. After installation of new cutting and slitting lines, our transformer core production will increase to 1.200 tons per month.

Which countries have EasyCore exported products?

EasyCore has been producing transformer cores and cut laminations for more than 20 countries from different regions of the World including Europe, Middle East, Africa and South America.

Is it possible to order “finished transformers” from EasyCore?

Definitely,yes. We have already produced more than 250 finished transformers.

Where is the factory located?

Our factory is located in Kocaeli which is very close to international shipping ports.

How long is the delivery period?

EasyCore is very fast in planning and producing the requested transformer cores beacuse of large stocks of electrical steel in our warehouses located in Germany and Türkiye.

Is EasyCore a Turkish company?

EasyCore is a multi-national company functioning in 3 different countries with offices, warehouses and factory.

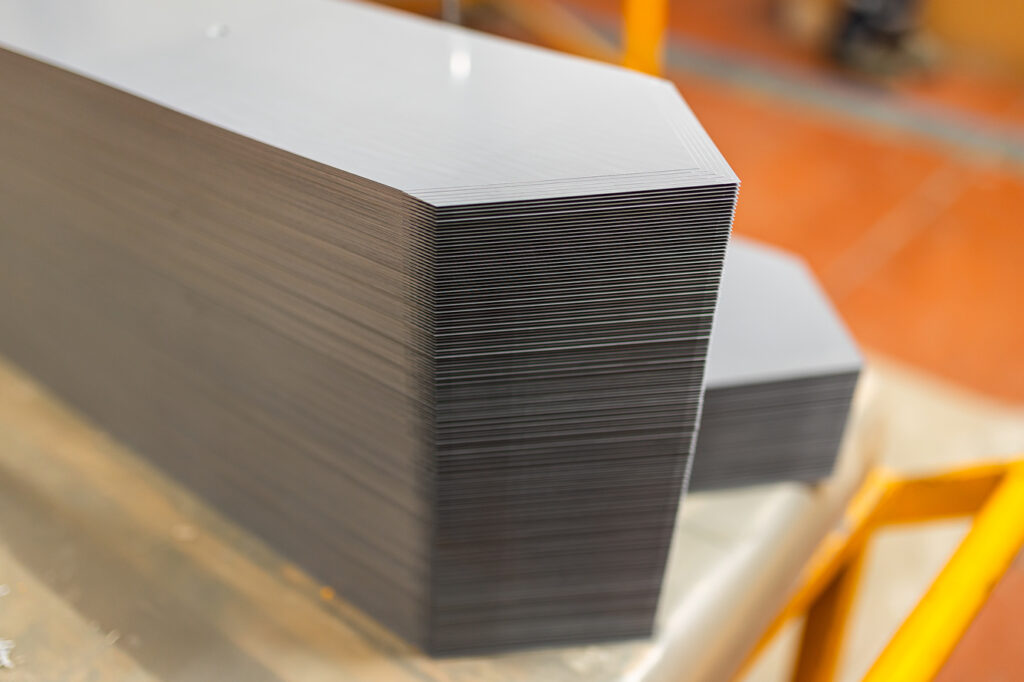

DISTRIBUTION TRANSFORMER CORES

EasyCore produces tailor-made distribution transformer cores in different sizes of machine lines to fulfill the custom needs of each customer within its worldwide network. Technical drawings received from the clients are examined and analyzed by an engineer team and a continuous communication with the client starts from the first order till the end of the production process.

POWER TRANSFORMER CORES

EasyCore has the ability to manufacture power transformer cores from different sizes and designs. All related parts of the cores are produced according to the need and request of its clients. Having received many orders from different parts of the world, the EasyCore team aims to keep on increasing capacity consistently.

MAGNETIC FLUX COLLECTORS

Known also as shieldings, the magnetic flux collectors are parts of the power transformers designed to lower power losses.EasyCore uses high quality grain oriented electrical steel to produce shieldings from 8 mm width and above for power transformers to ensure the best efficiency.